Copper in Manufacturing: Design, Performance, and Machining Advantages

Copper is a highly valued material in manufacturing due to its unmatched electrical and thermal conductivity. It plays a critical role in industries such as electrical, electronics, power generation, HVAC, renewable energy, and industrial equipment manufacturing. Copper’s ability to efficiently transfer heat and electricity makes it essential for components where performance, efficiency, and reliability are paramount.

In addition to its conductivity, copper offers excellent corrosion resistance and natural antimicrobial properties. While copper is softer and more expensive than many other metals, its performance advantages often justify its use in demanding applications. For components where conductivity and heat dissipation are critical, copper remains one of the most effective materials available.

Common Copper Grades and Their Uses

Copper is available in several grades, each tailored to specific performance requirements. Selecting the proper grade ensures optimal conductivity, machinability, and durability for the intended application.

C101 and C102 copper (oxygen-free copper) provide the highest electrical and thermal conductivity and are commonly used in high-performance electrical components, bus bars, and sensitive electronic applications. C110 copper (electrolytic tough pitch) is the most widely used commercial grade and offers excellent conductivity with good availability and cost efficiency. Other copper alloys are selected when improved strength, machinability, or environmental resistance is required while maintaining acceptable conductivity.

Designing Parts with Copper

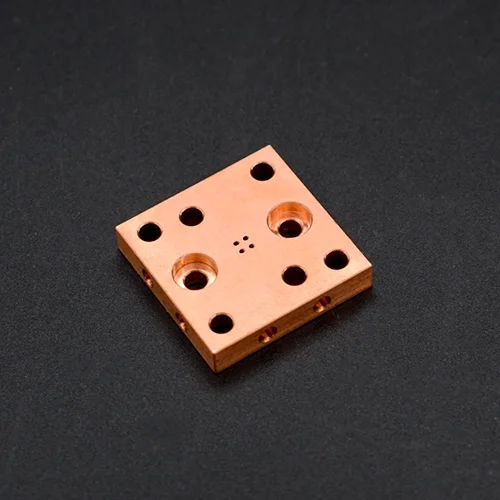

Designing parts with copper requires a focus on function-driven performance. Copper is often chosen for components that manage heat or electrical flow, such as connectors, terminals, heat sinks, and conductors. Designers can take advantage of copper’s conductivity to improve system efficiency, reduce energy loss, and enhance overall performance.

From a design-for-manufacturing perspective, copper’s softness must be considered. Thin walls, sharp edges, and delicate features can deform if not properly supported. Designers should use generous radii, realistic tolerances, and robust geometries to ensure parts maintain dimensional stability throughout machining and service life.

Machining Copper

Machining copper presents unique challenges compared to harder metals. Its softness and ductility can cause material to smear or produce long, stringy chips, requiring sharp tooling and carefully controlled cutting parameters. Proper chip control and coolant use are essential to achieve clean cuts and consistent surface finishes.

Despite these challenges, CNC machining can produce highly precise copper components when performed correctly. Copper responds well to secondary operations such as polishing, plating, and surface treatments, which can enhance conductivity, appearance, or corrosion resistance. With the right machining expertise, copper parts can meet extremely tight tolerances while delivering exceptional functional performance.