CNC machining (Computer Numerical Control machining) is a manufacturing process that uses computer-controlled machines to precisely cut, shape, and form raw materials such as metal, plastic, or wood into finished parts. A digital design file typically created using CAD software—guides the machine’s movements, tooling, and material removal with exact accuracy. This automation allows manufacturers to produce highly consistent, repeatable parts with tight tolerances, making CNC machining ideal for both prototypes and high-volume production.

There are several types of CNC processes, each suited to different part geometries and applications. CNC milling uses rotating cutting tools to shape stationary workpieces and is known for its versatility and ability to create complex features. CNC turning (lathe work) rotates the material while tools cut it, making it ideal for cylindrical parts like shafts and bushings. CNC drilling produces precise holes, often as part of a larger machining operation, while CNC grinding is used for ultra-precise finishes and tight tolerances, especially on hardened materials. CNC routing is commonly used for wood, plastics, and composites, and multi-axis CNC machining (4-axis and 5-axis) enables complex shapes with fewer setups. For extremely hard materials or intricate details, CNC EDM (Electrical Discharge Machining) uses controlled electrical sparks to remove material. Together, these processes make CNC machining one of the most reliable, accurate, and efficient manufacturing methods available today.

However, at Brooks Industrial, we currently only focus on CNC milling and CNC turning.

What is CNC Machining?

Brooks Industrial’s CNC Services

CNC Milling

CNC milling uses rotating cutting tools to shape stationary workpieces and is known for its versatility and ability to create complex features.

Other CNC services

CNC Grinding

CNC grinding is used for ultra-precise finishes and tight tolerances, especially on hardened materials.

multi-axis CNC machining

Multi-axis CNC machining (4-axis and 5-axis) enables complex shapes with fewer setups.

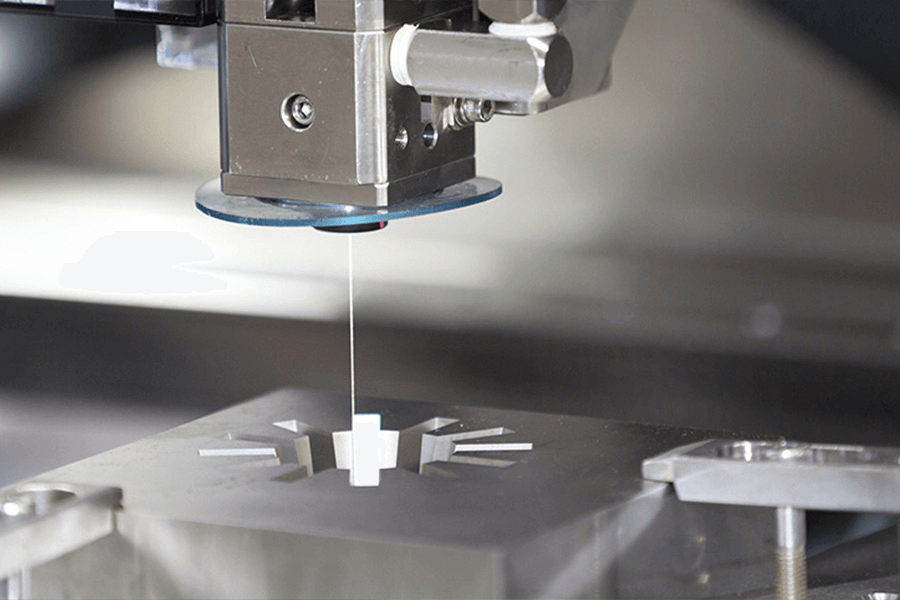

EDM (Electrical Discharge Machining)

CNC EDM (Electrical Discharge Machining) uses controlled electrical sparks to remove material

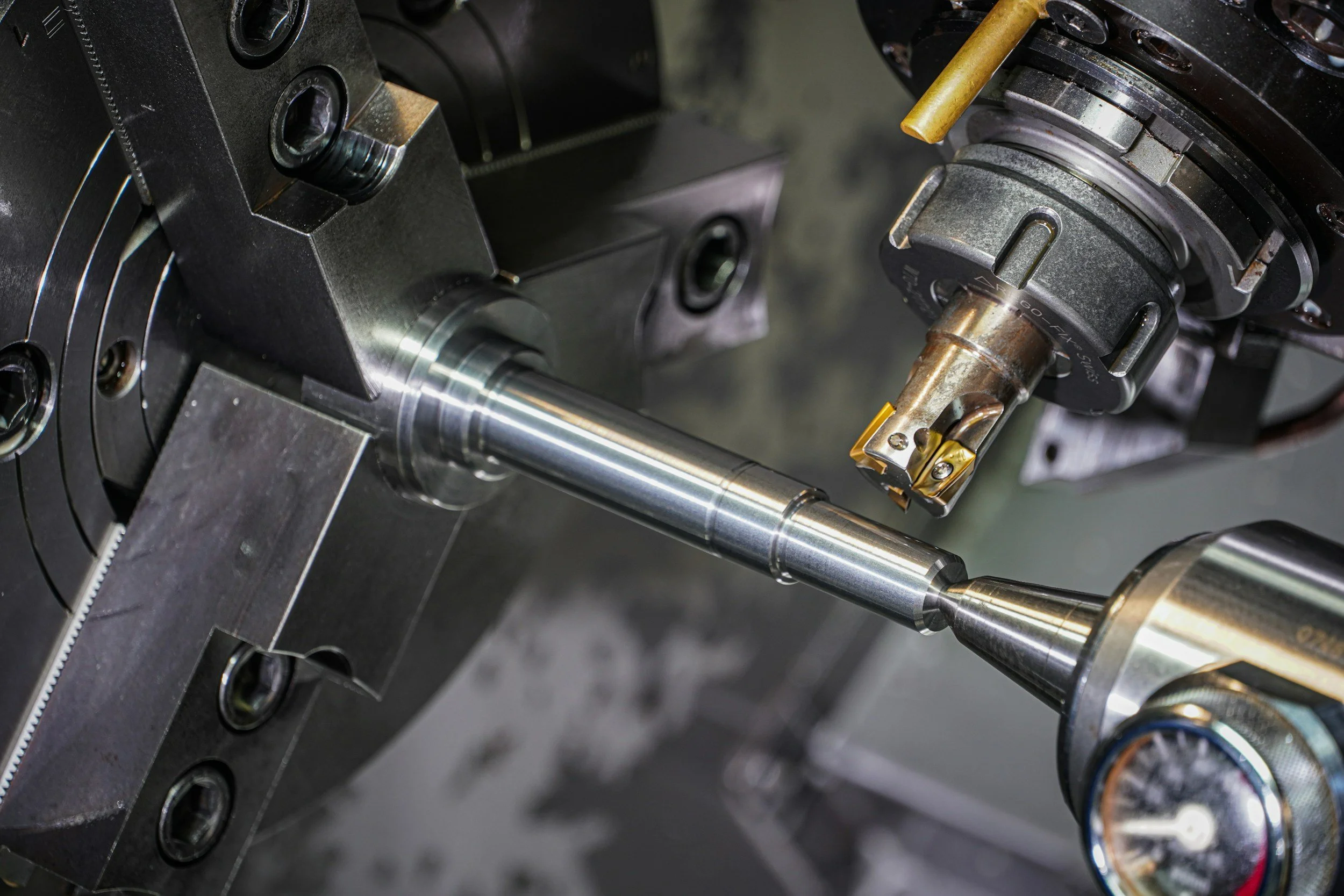

CNC turning (lathe work) rotates the material while tools cut it, making it ideal for cylindrical parts like shafts and bushings

CNC Turning

Material Choice

Choosing the correct material for your application is a critical step in ensuring part performance, reliability, and longevity. The right material must meet the mechanical requirements of the job—such as strength, hardness, weight, and wear resistance—while also accounting for environmental factors like temperature, moisture, corrosion, and chemical exposure. For example, aluminum is often selected for its lightweight strength and machinability, while stainless steel is preferred in corrosive or hygienic environments. Understanding how a material will behave under real-world operating conditions helps prevent premature failure and reduces long-term maintenance costs.

Material selection also impacts manufacturability, cost, and lead time. Some materials machine faster and more efficiently, lowering production costs, while others may require specialized tooling or longer cycle times. Availability, tolerances, surface finish requirements, and the need for secondary processes such as heat treating or coatings should all be considered early in the design phase. By balancing performance needs with budget and production efficiency, manufacturers can choose a material that delivers optimal results for both the application and the overall project.

Aluminum is lightweight, strong, and highly machinable, making it ideal for both prototypes and production parts. It offers excellent corrosion resistance and a strong strength-to-weight ratio for demanding applications.

Aluminum

Carbon Steel

Carbon steel provides high strength and durability at a lower material cost. It is commonly used for heavy-duty components where wear resistance and structural integrity are critical.

Stainless steel is valued for its superior corrosion resistance and long service life. It performs well in harsh, sanitary, or high-temperature environments while maintaining strength and appearance.

Stainless steel

Tool steel offers superior hardness, wear resistance, and strength at elevated temperatures. It is commonly used for tooling, dies, molds, and high-wear components.

Tool Steel

Titanium combines extreme strength with low weight and outstanding corrosion resistance. It is well suited for aerospace, medical, and high-performance environments where reliability is critical.

Titanium

Brass machines easily and delivers tight tolerances with excellent surface finishes. It also offers good corrosion resistance and electrical conductivity, making it ideal for fittings and components.

Brass

Copper is known for its exceptional electrical and thermal conductivity. It is commonly used in electrical, heat transfer, and high-performance conductivity applications.

Copper

Engineering plastics are lightweight, cost-effective, and resistant to chemicals and wear. They are ideal for non-conductive, low-friction, or impact-resistant components.

Plastics (ABS, Nylon, Delrin/Acetal, Polycarbonate)

Composites provide excellent strength-to-weight ratios and corrosion resistance. They are often used in applications requiring lightweight structures or electrical insulation.