Titanium in Manufacturing: Design, Performance, and Machining Advantages

Titanium is a premium engineering material valued for its exceptional strength-to-weight ratio, corrosion resistance, and performance in extreme environments. It is as strong as many steels while being significantly lighter, making it a preferred choice in aerospace, medical, defense, energy, and high-performance industrial applications. Titanium also resists corrosion from saltwater, chemicals, and high temperatures, allowing parts to perform reliably where other materials fail.

Although titanium carries a higher material and machining cost, its long service life and performance advantages often outweigh the initial investment. In applications where weight reduction, durability, and reliability are critical, titanium can dramatically improve efficiency and reduce maintenance over time. These qualities make it a strategic material choice rather than a commodity option.

Common Titanium Grades and Their Uses

Titanium is available in several grades, each designed to balance strength, ductility, corrosion resistance, and machinability. Selecting the correct grade is essential to achieving optimal performance while controlling manufacturing cost.

Grade 2 titanium is commercially pure and offers excellent corrosion resistance with good formability and machinability, making it ideal for chemical processing, marine, and industrial applications. Grade 5 titanium (Ti-6Al-4V) is the most commonly used alloyed grade and provides outstanding strength, fatigue resistance, and heat tolerance, making it a standard in aerospace, medical implants, and high-performance components. Other grades, such as Grade 9, offer a balance of strength and formability for applications requiring moderate performance with improved machinability.

Designing Parts with Titanium

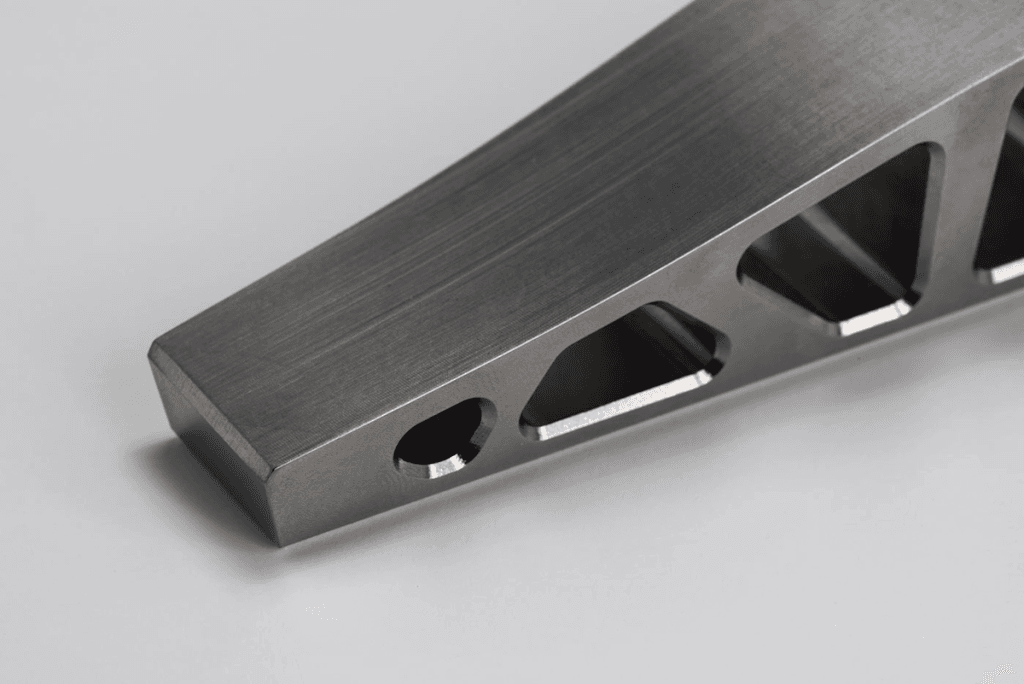

Designing parts with titanium requires a careful balance between performance and manufacturability. Titanium is often chosen for parts subjected to high stress, vibration, or corrosive environments, where failure is not an option. Designers can take advantage of titanium’s strength-to-weight ratio to reduce mass while maintaining structural integrity, which is especially valuable in aerospace and motion-sensitive applications.

From a design-for-manufacturing perspective, titanium benefits from conservative tolerances, smooth transitions, and generous radii. Sharp corners and thin features can increase machining time and tool wear. Designers should also consider the full production process, including potential stress relief or finishing operations, to ensure the part performs as intended without unnecessary cost or rework.

Machining Titanium

Machining titanium is more challenging than machining aluminum or steel due to its low thermal conductivity and tendency to retain heat at the cutting edge. This can lead to increased tool wear if cutting parameters are not carefully controlled. Slower cutting speeds, rigid setups, sharp tooling, and consistent coolant application are essential for successful titanium machining.

Despite these challenges, CNC machining allows titanium components to be produced with exceptional accuracy and repeatability. Titanium responds well to secondary processes such as polishing, anodizing, and surface treatments that enhance wear resistance or appearance. When machined by experienced professionals, titanium delivers high-performance parts capable of operating in the most demanding environments.